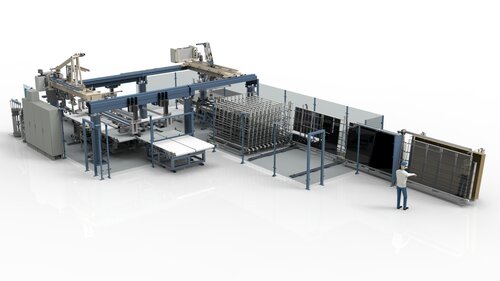

Automatic glass pane gluing machine - GVA 115W.K

Precision gluing of panes into sashes

LEMUTH’s glass gluing machine guarantees the accurate and neat gluing of panes into the sashes. The machine needs 60 to 65 seconds to apply the glue to a standard surface area of 1 m x 1.2 m. The composition of the profile to be processed must be adapted accordingly, meaning, the slot between the glass pane and the rebate base of the sash will be reduced to 3 – 4 mm to minimise the amount of glue required. A reduction of the slot is possible since this gluing method does not require using wedges for the glass pane.

Fully automated processing

After the operator has inserted the pane of glass into the sash of the fully assembled window frame on the preceding loading rack, the machine takes the window for further work. Individually driven conveyor belts on the lower and the back side of the machine ensure that the unit is transported gently. Before gluing, the window unit is automatically clamped to the rear panel of the machine. The glue is inserted around the entire periphery between the glass compound and the glazing rebate. After application the window units are loaded off the machine. The glazing beads are then assembled. Shortly afterwards it is possible to gently feed the window unit onwards.

High-tech down to the very last detail

Via an automatic plausibility check the machine controls the exact thickness of the glass. Further-more, when using hot melt adhesives, a specific mechanism has been integrated for the alignment of the glue stream. This ensures that the injection nozzle always glides at the optimum injection angle to the profile section. The heated glue nozzle stand-by position prevents the glue from hardening during periods of inactivity. When using silicones or 2-component polyurethanes the nozzle is equipped with a compensating element to balance out any deviations in the profile section. The nozzle glides along the surface of the glass.

Gluing of numerous user-defined panels

The machine can process windows with any number of sashes. After the parts have been recognised using a barcode reader the control system processes all the necessary information from the data record for the machining of the parts.

Windows-PC and fast remote-access

A convenient industry PC with windows-XP is available for data input. For fast remote-access there is an integrated modem.

Gluing affords greater stability

Gluing technology delivers a much higher level of stability. The number of subsidences or deformations is noticeably reduced. The gluing of PVC sashes in glazing rebates of up to 2 m also dispenses with the need for steel reinforcements. It is also possible to narrow the profile of the sash itself resulting in an additional savings on materials. The sash is lighter. The greater rigidity of the unit facilitates the production of larger sashes.

Outstanding Thermal Insulation

The glued sashes are completely wind proof. Ele-ments with standard glazing improve the insulation value by 20%. Windows with such good characteristics are optimal for use in passive and low-energy houses.

Advantages of gluing panes

- No pad insertion necessary

- Mechanical pre-priming only necessary for sashes

- Slender appearance (more light in the living space)

- About 20% better insulation in profile cross section

- Improved sound insulation (the glue acts as an absorber)

- Better security and protection against break-ins due to improved connection between glass and sash

- Glass pane units can be replaced at any time

HORIZONTAL machining position - optimised for gluing in the sash overlap

In this configuration, the glue is usually applied to the inside or the outside of the sash overlap. High-precision handling units fully automatically perform all work processes such as loading the sash, applying the glue and inserting the glass in a precise manner. Because it is mainly wooden sashes that are glued in the overlap, the sash can be aligned precisely at right angles by means of the clamping table. Once the glue has set, the aligned sash will retain its shape permanently.

Latest modification: 07.02.2022